Toll Free: 877-355-7577

Phone: 262-785-7577

Fax: 262-785-1066

Email: sales@bct-us.com

![]()

West Allis, WI 53214 USA

Parts and Machinery for the Abrasive Blast Industry

1.25 Cubic Foot Air Blast Barrel

Features:

- 150 LB. Load Capacity

- (3) Blast Nozzles

- 115 Volt - Single Phase

- Continuous Molded Rubber Belt

- Low Noise Level

- Safety Interlocks

- Reversing Mill

- Automatic Timer Controls

- Machine Warranty

- Low Profile Design

- Standard Color is Coyote

Air Blast System

| Air Blast Nozzles: | Three 3/8" diameter Venturi carbide nozzles with 3/16" diameter air jets are standard. full coverage of blast chamber is accomplished. Height of nozzles to the work is adjustable. |

Cabinet Construction

| Cabinet: | Formed to maintain structural integrity. The cabinet is fabricated from 1/4" steel plate. Access holes in sides of cabinet to simplify belt replacement. Access door in back of cabinet permits removal of trapped material collected on abrasive screen. |

| Door: | One piece polyurethane door opens and closes easily and provides full access to blast chamber Door is positively sealed from abrasive and dust leakage. |

| Work Loading Height: | 40" |

| Work Load Capacity: | 17" wide x 20" diameter mill will handle 1.25 cubic feet or 150 LBS. |

| Conveyor: | Continuous molded rubber tumble belt is (2) ply construction with 1/8" diameter abrasive drain holes. Rubber tumbling ridges are molded directly onto the belt. |

| Conveyor Rollers: | Rollers have 1 3/16" diameter solid shafts. All rollers are mounted to the cabinet with standard (4) bolt flange bearings. |

| Conveyor Speed: | 4.8 feet per minute. |

Power and Air Requirements

| Electric: | Simple 115 Volt - single phase. |

| Electric Motors: | All motors are totally enclosed and fan cooled to provide maximum life. Unit optionally equipped 230 volt - single phase or 230-460 volt - 3 phase. |

| Electric Motors: | All motors are totally enclosed, fan cooled, to provide maximum life. |

| Mill Drive: | 1/2 HP, 1800 RPM |

| Air Requirement: | 100-120 CFM @ 60-80 PSI. 3/4" NPT furnished for air connection. |

Separator System

| Abrasive Screening: | Abrasive screening in cabinet eliminates tramp material from abrasive. |

| Abrasive Separator: | 600 CFM centrifugal for optimum sizing of contaminate removal. |

| Abrasive Required: | 50 pounds for initial start-up. |

| Dust Collector: | 600 CFM, minimum required. |

Safety and Structure

| Safety: | Blast nozzles operational only when door is closed. Chain drive is fully guarded. |

| Noise Level: | Approximately 80 DB |

| Shipping Weight: | 1,100 pounds |

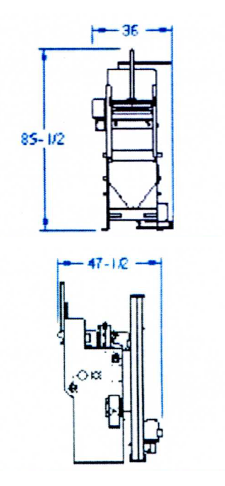

| Machine Dimensions: | 29" wide x 37" deep x 69" tall |

Additional customization is available to fit specific requirements.

In the News

Tumble Blast Machines

1.25 Cubic Ft. Air Blast Machine

1.25 Cubic Ft. Airless Blast Machine

3 Cubic Ft. Air Blast Machine

3 Cubic Ft. Airless Blast Machine

6 Cubic Ft. Air Blast Machine

6 Cubic Ft. Airless Blast Machine

Table Blast Machines

48 Inch Table Blast Machine

70 Inch Table Blast Machine

Model 2460 Spinner Hanger

Model 3072 Spinner Hanger

Other models available.

616 Dust Collectors

632 Dust Collectors

70 Push Table Video

48 Inch Table Blast Video

1.25 Cubic Foot Tumble Blast Video

Pass-Through Blast Video

Spinner Hanger Video

Dimensions